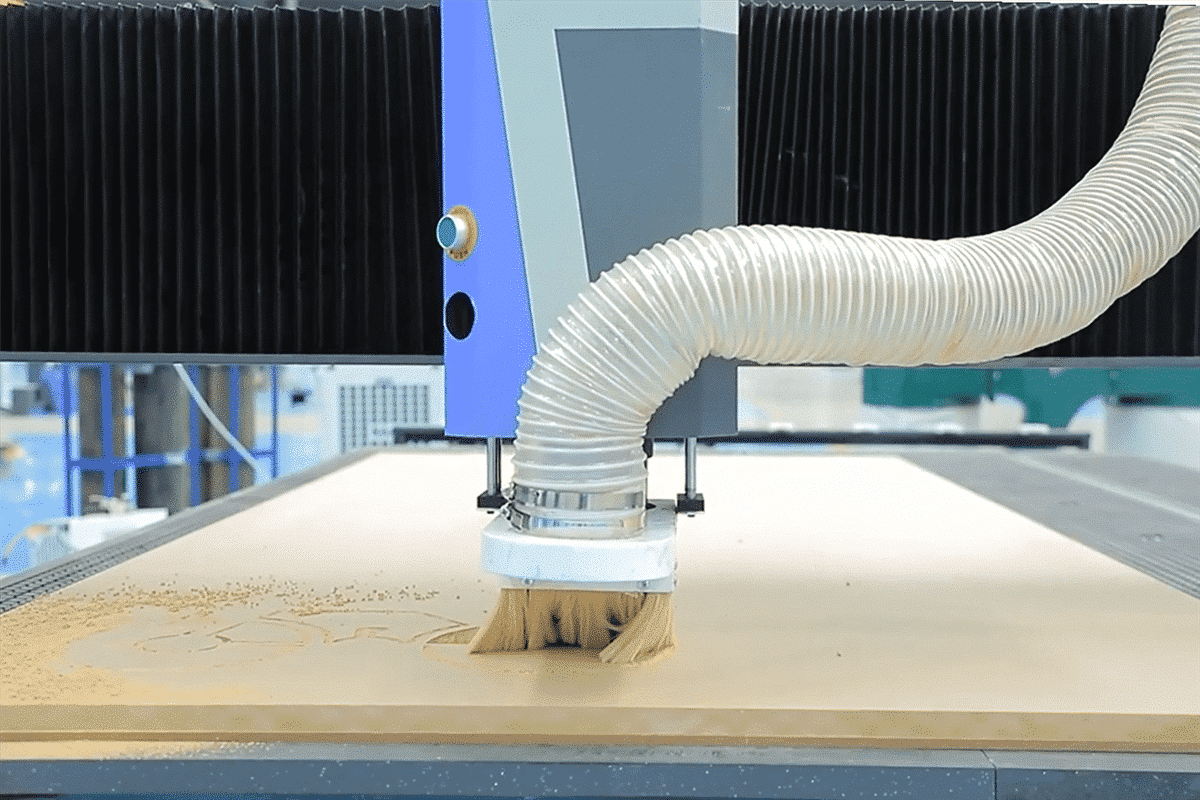

Cutting MDF on a CNC router can present a range of challenges. Understanding how to troubleshoot these issues is beneficial for maintaining high-quality results and prolonging tool and machine life. Here are common problems that arise when cutting MDF and how to address them effectively:

Rough Edges or Chipping

The cut edges of MDF appear rough, frayed, or chipped. Here is the solution:

Use a compression bit designed specifically to minimize chipping on the top and bottom surfaces of MDF.

Adjust the feed rate and spindle speed to achieve a smoother cut.

Try a climb milling approach to reduce splintering, especially when cutting intricate shapes.

Consider using a light scoring pass along the intended cut path before making a full-depth cut.

Burn Marks on MDF

The edges or surfaces of the cut MDF show burn marks. Here is the solution:

Reduce spindle speed or increase the feed rate to prevent the tool from lingering in one spot and generating heat.

Ensure the cutting tool is sharp; dull bits create more friction and heat.

Consider using a misting or air-cooling system to cool the bit and reduce heat buildup during cutting.

MDF Splitting or Cracking

The MDF splits or cracks during cutting. Here is the solution:

Ensure that the MDF sheet is well-supported and secured to the worktable to minimize movement or vibrations.

Use gradual depth passes rather than a single, deep cut to reduce stress on the material.

Verify that the toolpath does not exert excessive lateral force on the MDF.

Inconsistent Cut Depths

The depth of cut varies across the material, leading to inconsistent results. Here is the solution:

Check that the CNC router bed is level and properly calibrated.

Ensure the MDF sheet is flat and securely clamped to prevent lifting during cutting.

Inspect the CNC router spindle and tool holder for any play or looseness.

Poor Finish on Cut Surfaces

The cut surface appears rough or uneven. Here is the solution:

Use higher flute-count bits for a smoother finish, but be mindful of potential dust clogging.

Reduce feed rates slightly to allow for a more precise cut.

Consider performing light sanding or using finishing tools after the cut for a refined surface.

By understanding the cause of these common issues and making the necessary adjustments, you can improve the performance and cutting quality of your CNC router when working with MDF. Regular maintenance of the CNC router and using the right tools for the job are key factors in achieving consistent results.

Comments on “Common Troubleshooting for CNC Router Cutting MDF”